The efficiency of modern mine enterprises profits from advanced technology, while the advanced technology is reflected in the customized and reasonable technology flow and high-quality mine equipment.

For most mine, the early processing plant construction is beginning with the mineral processing experiment report. The final result of mineral processing experiment is directly related to the mineral processing plant investment and the cost after production. Therefore, the mineral processing experiment is the resource of mineral processing, the direction of mine design, and the key of investment.

On this point, Xinhai Mining established Yantai Xinhai Mine Research Design Co. LTD, which is developing the special research & design and project technology. Xinhai Mine Research Institute consists of laboratory, laboratory and process debugging section. In more than 20 years of processing plant practice it has accumulated excellent professional knowledge and rich practical experience, and strives to win the ideal recovery rate for customers through rigorous tests, accurate data, detailed reports.

At present, Xinhai Mine Research & Design Testing Center passed the CNAS International certification, completed 180 experiment research projects annually, and the test reports all meet the industry standards. At the same time, it has guided the design and production of processing plants to an average of 80 annually. The test level has reached the international advanced level, and it has obtained a number of authorized invention patents. Many academic papers have been published in some authoritative journals such as CHEMICAL MINERALS AND PROCESSING, GOLD, WORLD NON-FERROUS METALS, etc. The professional book NEW RESEARCH RESULTS AND APPLICATIONS OF GOLD AND SILVER DIFFICULT TO REFINE has made outstanding contributions to the research field of mineral processing in China.

I.What mineral processing experiment can we provide?

I.What mineral processing experiment can we provide?1.The kind of mineral processing experiment service

Xinhai Mine Research Institute mainly carries out the experiment in the laboratory. Through a wide range of exploration and research on ore samples, the application of various methods, the strict control and change of the research object and process, the rapid and reasonable processing technology solution of the process program, it can provide the dressing test in the mineral exploration work , the dressing test before the design of the concentrator and the dressing test of the production site. The purpose is to determine the separation method of main components and the possible separation index, and to evaluate whether it is technically feasible and economically reasonable. To test different types and grades of ores, points out that the various types of washability differences, both in preparation for the next test and can be taken as the basis for design of processing plant and improved on the basis of industrial production.

The characteristics of mineral processing experiment

(1)Carry out in the laboratory

It is generally through the sample or model to study the whole or prototype.

It can use a small number of samples, less manpower and material.

The sample or model should be consistent with the prototype.

(2)It can be researched and explored on a wide range of scales

Laboratory studies may not be restricted by production conditions, using various methods to control and change process of the research object.

You can understand the knowledge that is not easily or even impossible to obtain in production practice.

It can provide a theoretical basis and open up a new way for the development of mineral processing.

2.Types of different ore service

Xinhai Mine Research Institute can provide accurate mineral processing experiment for ferrous metal ore, nonferrous metal ore, precious metal ore, rare earth metal ore, rare metal ore, dispersed metal ore, metallurgical auxiliary raw material mineral, chemical raw material nonmetallic mineral, building materials and other nonmetallic mineral and more than 70 kinds of minerals.

II.How to carry out the mineral processing experiment?The processing outlet is determined by the test idea, and the result determines the result. During the mineral processing experiment, it mainly includes the preparation stage before the ore dressing test, the ore dressing process stage and the ore dressing result stage. Xinhai Mine Research Institute grasps the nature and type of ore, determines the recoverable valuable elements, preliminary explores of the dressing process conditions through the raw ore determination of mineral properties. And according to the test results, it customizes the ore processing process, to ensure the ore recovery rate and provides technical support for the design and production.

1.The preparation before mineral processing experiment

(1)Data collection

To understand the research and production of the same or similar ores.

Understanding of future application mines.

(2)To determine the weight of the sample

Is the sample size the same for each test?

What is the weight of each test sample?

What is the total quantity of samples required?

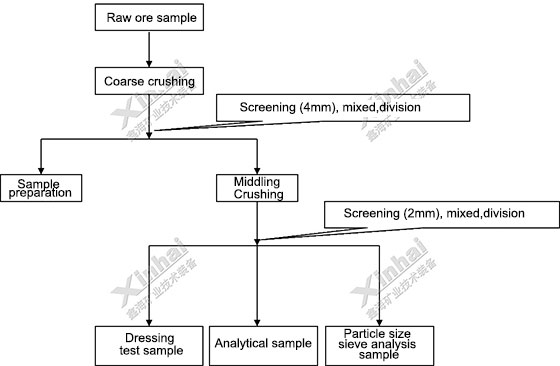

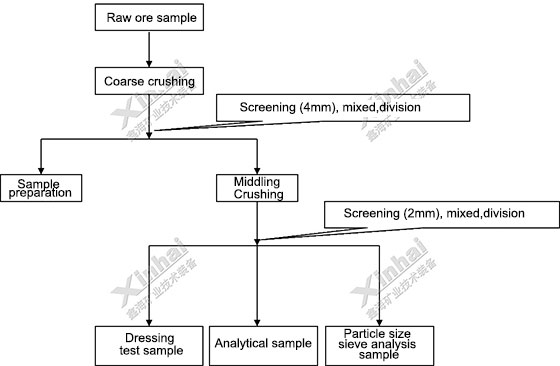

(3)Sample preparation

The preparation of samples mainly includes material composition research samples (including rock ore identification, microscopic analysis, elemental analysis, phase analysis, spectral analysis, gold-testing analysis, chemical analysis samples), ore washing and pre-separation samples (hand separation, heavy medium samples), heavy separation test samples, laboratory flotation and magnetic separation samples.

Material composition study sample

Rock ore appraisal: the purpose is to understand the intercalation and intercalation relation of the mineral in ore.

Microanalysis, elemental analysis, phase analysis, spectral analysis, assay analysis: in the final product shrinkage, generally is crushed to 1~3mm after shrinkage, and then grinding to less than 0.1mm.

Chemical analysis sample: generally less than 0.074mm.

Washing ore and pre-dressing sample (hand dressing, heavy medium sample) : same size as original.

Gravity separation sample:

Generally, it is determined according to the selected grain size. If the selected grain size cannot be determined, it is determined according to the chimeric grain size of the useful mineral. If it is assumed that the possible inclusion particle size is 10mm according to the Mosaic particle size, several particle size preparation tests such as 10~0.5-0.2~0mm can be prepared. At the same time, the weight of a single test is determined according to the specification of the equipment used in the laboratory.

Laboratory flotation and magnetic separation sample:

Grind to laboratory grinding grain size (1~3mm), but it is necessary to note that only one batch of single samples can be prepared at a time, the rest must be kept in a relatively coarse grain size.

(4)Preparation of ore dressing test plan

The ore processing method and the sequence to be used in the test, including the ore processing method, the ore processing process and the ore processing equipment, can be used according to the ore properties of heavy, magnetic, floating, chemical treatment or joint process.

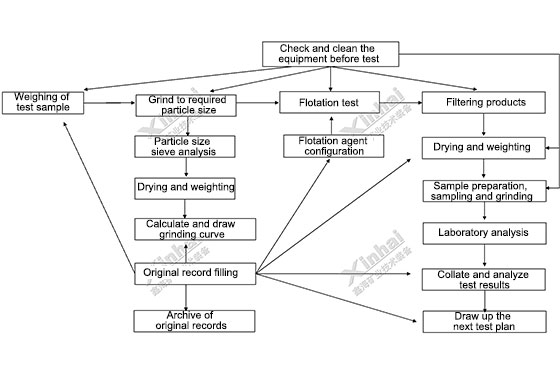

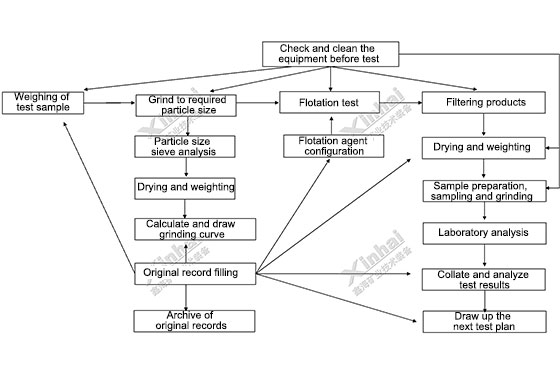

2.The course of mineral processing experiment

(1)The research of mineral processing method

With the development of mineral processing technology, a variety of ore processing methods can be used. Therefore, in the test should be based on the ore properties, customer requirements for product quality and construction conditions, etc., the multi-program comparison test of dressing methods should be carried out selectively, and a reasonable dressing method should be selected.

(2)The experiment of processing condition

It mainly includes flotation test, magnetic separation test, calcination magnetic separation test, gravity separation test, electric separation test and so on.

Flotation test: Grinding fineness, pulp concentration, pulp temperature, pulp ph, reagent system, stirring and flotation tests were carried out. In some cases, tests should be carried out on the utilization of backwater, water quality, detoxification and desilting. Among them, the separation agent test should be combined with different separation methods to the main separation agent types, agent performance, dosage of agents and separation effect of the comparison test, choose the separation index is good, cheap, sufficient sources, little environmental pollution or easy to control the variety.

Magnetic separation test: Generally, magnetic induction intensity, material inclusion size, processing capacity, material classification and non-classification comparison test are carried out. The effect of ore water on the separation index and the effect of washed ore and unwashed ore on the separation index should also be tested for dry magnetic separation.

Calcination magnetic separation test: The calcining atmosphere, calcining temperature, calcining time, fuel type, dosage, volatile components, material size and other conditions were tested and the relevant technical parameters were determined.

Gravity separation test: Generally, ore washing classification is carried out, and then, in the case that the material layer is a single ore particle, a comparative test is carried out on the relationship between ore feeding particle size and treatment capacity.

(3)Mineral processing product inspection

Content: grinding mineral products, concentrate products, mineral products, tailings products, classified products. Different products have different contents.

Inspection method:

Screening or water analysis of mineral processing products;

To determine the chemical and mineral composition of each grain grade as required;

Sedimentation test was carried out on ore dressing products.

3.The result of mineral processing experiment

In mineral processing experiment, it analyzes the variation and efficiency through the original data from test. After the test, the obtained original data must be selected from the rough and refined, the false and the true, from here to there, from the surface to the inside of the sorting, correct and scientific processing of the test data, forming a high accuracy of the test results of the dressing test report.

III.What are the advantages of Xinhai Mine Research Institute?

III.What are the advantages of Xinhai Mine Research Institute?1.Provide accurate mineral processing experiment for more than 70 kinds of ores

The laboratory has a complete set of modern advanced equipment, such as crushing, fine grinding, roasting, drying, spectrometer, atomic fluorescence spectrometer, atomic absorption spectrophotometer, infrared ore analysis and detection.

The mineral processing research laboratory is equipped with crushed sample room, rock ore appraisal and Bond (Bond) grinding work index test, intelligent laser particle size detection, etc. It can provide experiment through gravity separation, magnetic separation, flotation, adsorption, bacteria oxidation, cyanide leaching and acid leaching and wet processing, special processing, heap leaching, tailings concentration and dry all kinds of mineral processing methods, such as test, and provides the reasonable processing technology.

2.Insist on carrying out mineral processing experiment with innovation thoughts

Xinhai Mine Research Institute adopts innovative thinking to make test plans for each kind of ore sample, and fully considers the characteristics of each kind of ore. There are 28 innovative technological plans for gold ore dressing alone.

3.The complex test of multi-ore point starts from the representative of ore sample

Many mines are multi – point ore supply, the mineral properties of each point are different. Representative sample collection method has been developed by Xinhai Mining:

Mining capacity planning and design – mining planning sampling test equipped with different kinds of samples – with the sample test, vice samples test – the final recommendation from the dressing – design – construction – according to plan in advance mining ore mining capacity planning and design in accordance with planning at the location of concentrator with ore – dressing production.

IV.Classic mineral processing projects

IV.Classic mineral processing projectsGuinea 6000tpd gold processing project

Ore characteristic: In this project, the raw ore is main oxide ore, and the 80% is powdery clay ore with particles of gold. The average grade of ore is 1.0g/t with less impurities, and gold is the only recoverable element.

Xinhai Solution: One stage closed grinding and classification – gravity separation – cyanidation leaching – electrolysis desorption, smelting – tailing treatment

In this project, 80% ores are powdery clay ore. The water content of raw ore is 25-30%. On the one hand, Xinhai Mining solves the block and feeding problems of powdery clay ore. On the other hand, Xinhai Mining applies gravity separation and cyanidation process, strengthen the gravity separation and grinding process. A part of gold particles are recovered in gravity separation, reducing the gold grade to leaching operation. Therefore the agent consumption amount is reduced, and so is the processing production cost.

Uganda 720tpd phosphate processing project

Ore characteristic: In this project, the metal is rich in iron , phosphorus and other metal. The ore consists of redual mineral detritus formed by the weathering of unconsolidated igneous carbonates and the epigenic fibronecalcite and earthy hematite clays. The large amount slime interference the extraction of apatite, magnetite and other ores. Each mineral is wrapped in each other, and it is not easy to grind and dissociate. The phenomenon of mineral homology is serious, and the titanium, iron, manganese, aluminum and magnesium lattice replace each other, which makes the mineral composition very complicated.

Xinhai Solution: Deslime – one stage closed grinding and classification – one stage coarse flotation, one stage scavenging flotation and two stage concentrating flotation – concentrating tailings dewatering.

In grinding stage, the ball mill, pump and classifying hydrocyclone constitute the one stage closed grinding system. The overflow of classifying hydrocyclone flows to the high efficiency agitation tank, and enter the flotation flow after mixed with the agents. In flotation stage, the flotation concentrates are sent to the concentrate pumpbox though foam pump. In concentrate tailings dewatering stage, the concentrates pumps to dewater in the concentrate dewatering system, and the product is phosphate concentrate. The flotation tailings are sent to the tailings dewatering system by tailings pump. The dry tailings after dewatering are transported to tailings depot by dumper. The dehydrated filtrate is returned to the production cycle for use.

Malaysia 700tpd gold processing plant

Ore characteristic: The mineral composition of the project ore is simple. The metal mineral is main pyrite, and the non-metal minerals are mainly quartz, calcite, mica and so on. The gold grade of raw ore is 4.70g/t. The silver grade is 4.63g/t. The iron is 20.10%, and sulfur is 20.55%. The recoverable element is gold.

Xinhai Solution: Two stage closed grinding – thickening before leaching – leaching absorption – tailing dry stacking

Two stage closed grinding is applied for grinding stage. The grinding product is screened by chip screen. The product under screen flows to the thickener. After thickening, the underflow of thickener is pumped to leaching operation. The gold bearing carbon is received through leaching, absorption, and carbon lifting, which is dealt with in the original gold factory. Leaching tailings dewaters in filter press. The back water is returning to the system, and the dry tailings depot in the tailings pond.

Morocco 500tpd silver processing plant

Ore characteristic: the metal mineral is natural silver, pyrite, hemitite and other ores. The gangue minerals includes quartz, feldspar, clay minerals and so on. The recoverable element is silver.

Xinhai Solution: Two and a half stage closed crushing – two stage grinding – flotation (one coarse, three scavenging, two concentrating) – two stage dewatering

In the crushing stage, Xinhai Mining applies the crusher and vibrating screen as two and a half stage closed crushing circuit. It reduces the crushing particle size obviously, and also reduces the load of grinding machine.

There is no the same mines in the world. Every mine should choose its suitable processing technology solution and equipment configuration. Xinhai Mining consists developing innovative technology and equipment quality at the same time, with strong technical strength as the core competitiveness and open-minded for every mine, customizing suitable processing technology and equipment and provide ideal mine efficiency.

zz540045886@gmail.com

zz540045886@gmail.com Chat

Chat