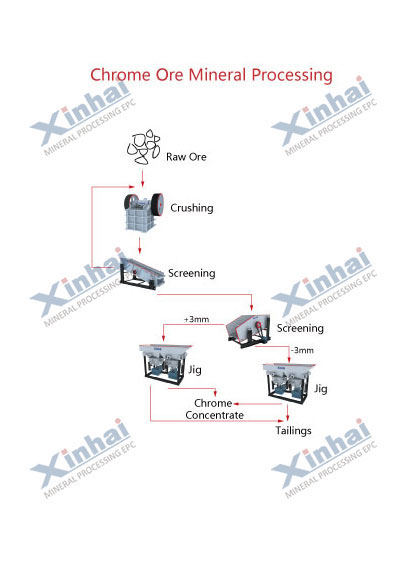

【Process Description】

1.Large raw chrome ore for primary crushing are fed into the jaw crusher by Plate feeder and are reduced to 8 inches or smaller. After first crushing, the material will transferred to cone crusher by belt conveyor for secondary crushing; the crushed chrome ore stone will then transferred to vibrating screen for classifying. After classifying, the parts whose size below the mesh size will be transferred away as final products, while the other parts will return to cone crusher, thus forming a closed circuit. Size of final products can be combined and graded according to your specific requirement.

2.The smaller crushed chrome ore is fed to ball mill for grinding. Inside the ball mill, the crushed chrome ore will grind the ore to about 0.2 mm with 3-inch steel balls.

3. Screened products are transported to the jig for rough separation and to three concentrating tables for fine separation. Then, tailings are delivered into the jig in the next stage for screening for 4 times like this. All tailings in the concentrating table are sent to tailings reservoir after tailings dry stacking.

【Case】

1. In crushing, it adopts traditional two-stage and a closed circuit system for ideal fineness. Besides, jaw crushers have large crushing capacity.

2. In grinding and classification, with characteristics of large processing capacity and small floor area, superfine lamination autogenous mill can save energy by more than 85%.

3. In classification, hydrocyclone and vibrating screen can enhance the classifying effects.

4. It adopts the third generation tailings dry stacking technology, which can save energy by 60-80%. Furthermore, it can also protect the environment and build a base for green mine.

Consult

Consult

Leave Message

Leave Message zz540045886@gmail.com

zz540045886@gmail.com