Here Are the Analysis and Solutions for Common failures of Flotation Cells!

2021-02-01 Xinhai Views (1223)

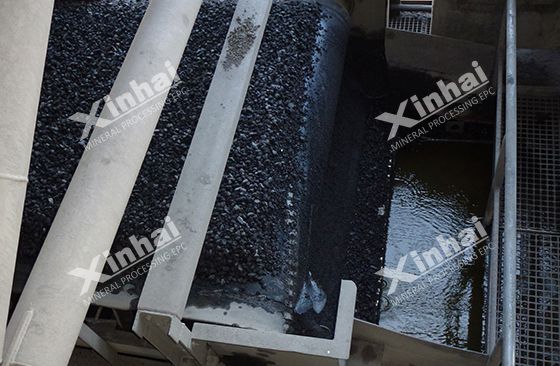

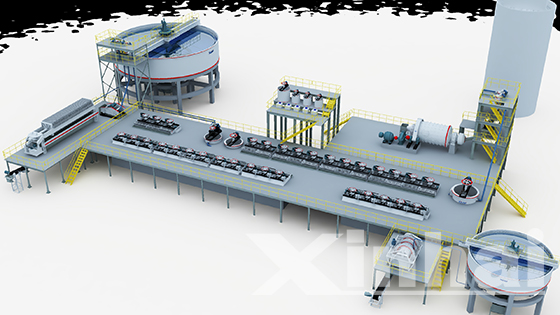

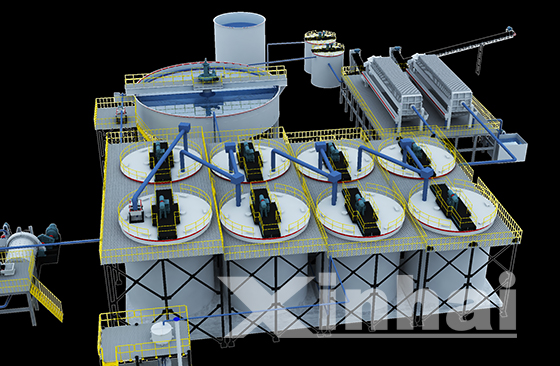

Flotation cell is one of the main equipment used in mineral processing plant for separation. In actual production, the flotation cell will encounter various problems from time to time. For example, the cover plate or stator screw falling off, the groove bottom is worn, the groove bottom guard plate is pried, the impeller cover plate is worn or corroded, and the scraper mechanism is not flexible, bearing clearance becomes large, etc.