【Advantages】

Rubber or plastic bands with oil resistance, acid and alkali resistance are adopted for materials with special properties. The head of conveyor belt with vulcanized linkage prolongs the service life greatly. Stable conveying, no relative movement between materials and conveyer belt Large capacity, simple structure, convenient maintenance, low operation cost and wide application.

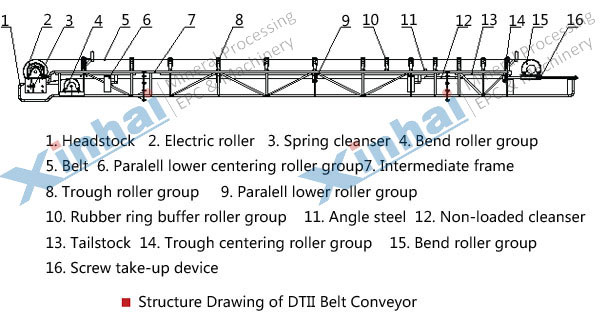

【Product Structure】

Belt conveyor is mainly composed of two end rollers and the closed belt which tightly set on it. The one driving the conveyor belt is named as the driving roller; the other one only used for changing the motion direction of the conveyor belt is named as the bend roller. The driving roller is drived by the motor through the reducer while the conveyor belt is dragged by the friction between the driving roller and the conveyor belt. The driving roller is generally installed on the discharging side to increase the traction and convenience to drug. Materials are fed by the feeding end, dropped on the conveyor belt, and discharged by the discharging end which is driven by the conveyor belt friction.

【Technical Parameters】

|

Belt Width B (mm) |

| Carrying Idler Type |

Belt Speed (m/s) |

500 |

650 |

800 |

1000 |

1200 |

1400 |

| Trough Idler |

Conveying Capacity Q (t/h) |

| 0.8 |

78 |

131 |

— |

— |

— |

— |

| 1.00 |

97 |

164 |

278 |

435 |

655 |

891 |

| 1.25 |

122 |

206 |

348 |

544 |

819 |

1115 |

| 1.6 |

156 |

264 |

445 |

696 |

1048 |

1427 |

| 2.0 |

191 |

323 |

546 |

853 |

1284 |

1748 |

| 2.5 |

232 |

391 |

661 |

1033 |

1556 |

2118 |

| 3.15 |

|

|

824 |

1233 |

1858 |

2528 |

| 4.0 |

|

|

|

|

2202 |

2995 |

【Successful case】

In a copper concentrator in northeast of China, the machines among different stages are far apart, the material composition of different stages is also different, through on-the-spot investigation, Xinhai specially added wear-resisting rubber that is researched and developed independently by Xinhai for the belt conveyor, which can convey spare parts with 500-2500 kg/m3 loose density and finished products, carry high temperature materials with 120˚, transport acid-base and oily material, as well as the material containing organic solvent, solved the problem of transportation in the plant.

【Related products】

Consult

Consult

Leave Message

Leave Message zz540045886@gmail.com

zz540045886@gmail.com