【Advantages】

Large air suction volume, low energy consumption

Each tank with air suction, slurry suction and floatation function does not need any accessory equipment to form floatation circle, which is convenient for process flow changing

The reasonable slurry circulation minimizes coarse sand sediments

Auto-control device of slurry volume, convenient adjustment

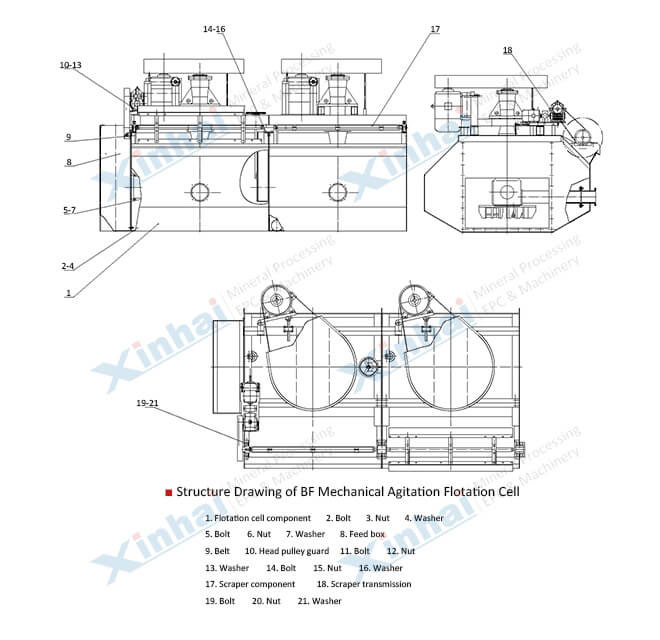

【Product Structure】

BF floatation cell is composed of impeller, cover plate, main shaft, the center tube, and tank etc..

The impeller is installed on tank main beam driven by V-belt and motor. The impeller is composed by double cones that produce strong slurry lower circulation. In addition, slurry auto-control device adjusts liquid surface.

BF flotation cell is widely used for separating non-ferrous metal, black metal, noble metal, non-metal mineral, raw body and materials of chemical industry, like gold flotation process, which are subject to roughing and cleaning of large and middle scale floatation plants.

【Technical Parameters】

| Model |

Effective

Volume

(m3) |

LXWXH

(mm) |

Impeller

Diameter

(mm) |

Circular Velocity of Impeller

(m/s) |

Air Suction Amount

(m3/m2.min) |

Motor Model |

Motor

Power

(kW) |

Capacity

(m3/min) |

Single Tank Weight (kg) |

| BF-0.15 |

0.15 |

550X550X600 |

200 |

6 |

0.9-1.05 |

Y112M-6 |

2.2 |

0.06~0.16 |

270 |

| BF-0.25 |

0.25 |

650X600X700 |

250 |

Y100L-6 |

1.5 |

0.12~0.28 |

370 |

| BF-0.37 |

0.37 |

740X740X750 |

286 |

7.2 |

Y90L-4 |

0.2~0.4 |

470 |

| BF-0.65 |

0.65 |

850X950X900 |

300 |

7.35 |

0.9~1.10 |

Y132S-6 |

3 |

0.3~0.7 |

932 |

| BF-1.2 |

1.2 |

1050X1150X1100 |

450 |

7.02 |

Y132M2-6

Y132M1-6 |

5.5

4 |

0.6~1.2 |

1370 |

| BF-2.0 |

2 |

1400X1450X1120 |

500 |

7.5 |

Y160M-6 |

7.5 |

1.0~2.0 |

1750 |

| BF-2.8 |

2.8 |

1650X1650X1150 |

550 |

8.06 |

Y180L-8 |

11 |

1.4~3.0 |

2130 |

| BF-4.0 |

4 |

1900X2000X1200 |

650 |

8 |

Y200L-8 |

15 |

2.4 ~4.0 |

2585 |

| BF-6.0 |

6 |

2200X2350X1300 |

700 |

7.5 |

Y225S-8 |

18.5 |

3.0~6.0 |

3300 |

| BF-8.0 |

8 |

2250X2850X1400 |

760 |

Y225M-8 |

22 |

4.0 ~8.0 |

4130 |

| BF-10 |

10 |

2250X2850X1700 |

7.52 |

5.0 ~10 |

4500 |

| BF-16 |

16 |

2850X3800X1700 |

850 |

8.7 |

Y280S-8 |

37 |

8.0 ~16 |

8320 |

| BF-20 |

20 |

2850X3800X2000 |

Y280M-8 |

45 |

10.0 ~20 |

8670 |

| BF-24 |

24 |

3150X4150X2000 |

920 |

Y315S-8 |

55 |

12.0 ~24 |

8970 |

【Successful case】

In 2008, an iron ore flotation plant in Sudan purchased Xinhai this type flotation machine. Each index of BF flotation cell is better than 5a flotation cell, single-capacity saves 23.96% power, in the case of the selected iron coarse and concentrate grade is lower than 20%, iron recovery rate increased by 6.58% through re-election of BF flotation cell, the energy consumption reduced by 15% ~ 30%, avoiding unnecessary waste of resources and saving a series of cost for the plant.

【Related products】

Consult

Consult

Leave Message

Leave Message zz540045886@gmail.com

zz540045886@gmail.com