【Advantages】

Stable, easy control, wide range of concentration.

Large capacity, enrichment ratio, high recovery rate.

Small cover space, less water consumption, simple structure design, no need of power.

Simple installation, convenient operation,less investment, quick return.

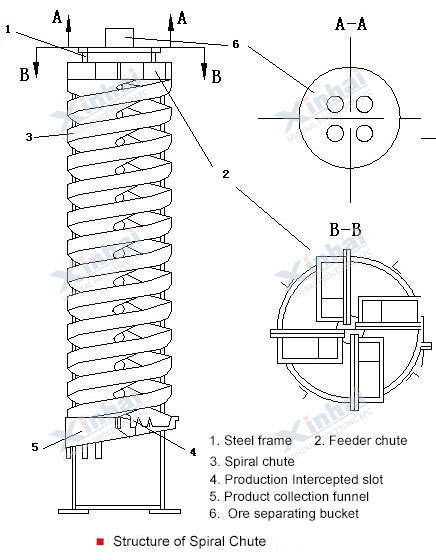

【Product Structure】

Ore pulps are uniformly fed into machine and form different layers as they pass across chute. Heavy minerals precipitate to bottom and are moved toward inner edge by the comprehensive action of various forces; light minerals are moved toward outer inner due to the speedy rotation. As a result, mineral particles with different density are divided into three zones------concentrate, middling and tailing.

Spiral chute is suitable for treatment of 0.6-0.03mm lode and placer, but high mud content is bad for separation. At present, spiral chute has been widely used in the treatment of iron ore, tungsten, tin ore, niobium tantalum ore, coastal and riverside placer and gold ore.

【Technical Parameters】

| Model |

BLL-2000 |

BLL-1500 |

BLL-1200 |

BLL-900 |

BLL-600 |

BLL-400 |

| Outside Diameter (mm) |

2000 |

1500 |

1200 |

900 |

600 |

400 |

| Screw Pitch (mm) |

1200 |

900, 675 |

900, 720, 540 |

675, 540, 405 |

450, 360, 270 |

240, 180 |

| Pitch Diameter Ratio |

0.6 |

0.48, 0.36 |

0.75, 0.6, 0.45 |

0.75, 0.6, 0.45 |

0.75, 0.6, 0.45 |

0.6, 0.45 |

| Lateral Dip Angle (degree) |

9° |

9° |

9° |

9° |

9° |

9° |

| Max. Screw Numbers Per Set |

3 |

4 |

4 |

4 |

2 |

2 |

| Feed Size (mm) |

2.00~0.04 |

0.8 ~0.037 |

0.3~0.03 |

0.3 ~0.03 |

0.2~0.02 |

0.2 ~0.02 |

| Feed Density (%) |

30 ~55 |

30 ~55 |

25 ~55 |

25 ~55 |

25 ~55 |

25 ~55 |

| Capacity (t/h) |

7~10 |

6~8 |

4~6 |

2~3 |

0.8~1.2 |

0.15~0.2 |

Overall

Dimension |

Length (mm) |

2120 |

1600 |

1360 |

1060 |

700 |

460 |

Width (mm) |

2120 |

1600 |

1360 |

1060 |

700 |

460 |

Height (mm) |

5600 |

5300 |

5230 |

4000 |

2600 |

1500 |

| Weight (kg) |

900 |

850/800 |

700/650/600 |

450/400/350 |

120/100/80 |

50 |

【Successful case】

A plant in Shandong seashore, the ore are mainly - 0.15 mm grade except for a small amount of bigger particles, the plant area is small, but the capacity is large. According to plant site and processing capacity, Xinhai spiral gravity chute manufacturer specially added wear-resisting rubber in the internal of spiral chute to increase its wear resistance, acid-resisting and corrosion resistance. The layered minerals is obvious in the operation, the machine service life is more half a year than ordinary spiral chute.

【Related products】

Consult

Consult

Leave Message

Leave Message zz540045886@gmail.com

zz540045886@gmail.com