【Advantages】

Small area taken, large capacity.

Slender body, flocculants are added in the process of concentrate; accelerate the particle settlement and dewatering process.

Reasonable structure, low energy consumption, high efficiency and low operation and maintenance cost.

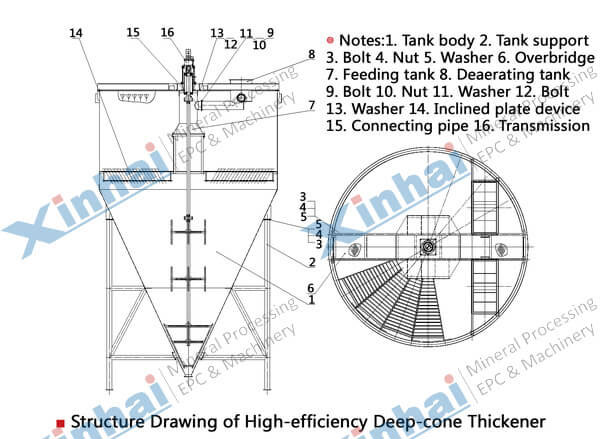

【Product Structure】

Deep cone thickener also called paste thickener is higher than other thickeners which consists of deep cone, feeding device, stirring device, control box, reagents adding device, automatic control system, etc.

Efficient deep cone thickener is mainly applied in thickening of minerals or other fine materials.

【Technical Parameters】

| Motor |

Tank Diameter(mm) |

Tank depth (mm) |

Sedimentation Area(m2) |

Capacity (m3/h) |

| GSNG-3 |

3000 |

4404 |

21 |

60-70 |

| GSNG-6 |

6000 |

8810 |

85 |

210-260 |

| GSNG-9 |

9000 |

13500 |

310 |

570-700 |

| GSNG-12 |

12000 |

17500 |

510 |

800-1200 |

| GSNG-15 |

15000 |

19000 |

1200 |

1000-1500 |

| GSNG-18 |

18000 |

22000 |

2000 |

1400-2100 |

| GSNG-20 |

20000 |

22800 |

2700 |

2100-2600 |

【Successful case】

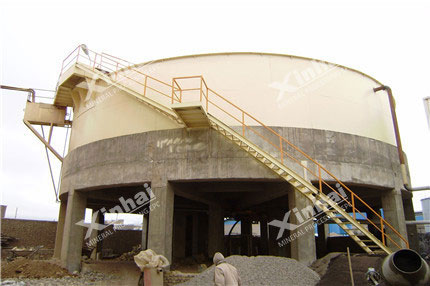

A copper mine concentrator is limited by site area, so the equipment are almost products which coves small area. In the thickening process, effective deep cone thickener solved this problem perfectly. Xinhai efficient deep cone thickener covers a small area, at the same time, the processing capacity is larger; the height is larger than diameter, the tank body is slender, speeding up the processing speed. In addition, the automaticity of Xinhai efficient deep cone thickener is much higher, more energy saving, and the cost control is more obvious.

【Related products】

Consult

Consult

Leave Message

Leave Message zz540045886@gmail.com

zz540045886@gmail.com