Xinhai Solution

-

01

The raw ore was washed by vibrating screen; washed ores were sent to the crushing system which adopted two-stage open-circuit process and produced a particle size of -15mm.

-

02

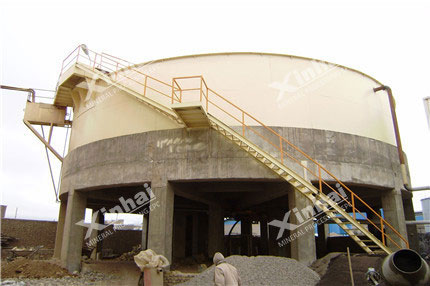

One-stage close-circuit grinding and classification was adopted; ground ground products were treated by trash screen; undersize slurry flowed to the thickener.

-

03

Thickener underflow was pumped by slurry pump to the trash screen; gold-bearing carbon was gained through leaching, absorption and carbon extraction; gold slime was produced after high-temperature high-voltage desorption electrolysis system; crude gold ingots were produced after smelting.

-

04

Leaching tailings were dehydrated with filtrate recycled and dry tailings stacked in the tailings pond.

Consult

Consult

Leave Message

Leave Message zz540045886@gmail.com

zz540045886@gmail.com 0086 180 0117 3032

0086 180 0117 3032