Energy Saving Ball Mill

【Introduction】:The new grooved annular liner increases the ball ore contact surface, strengthens the grinding effect, and has the ability to lift the ore, reducing energy consumption; the large double-row spherical roller bearing design can greatly reduce the friction and effectively Energy saving 20-30%, and easy to start; the small ball mill with a diameter of 2.1

【Capacity】: Up to 160t/h

【Improvement】: Cylindrical energy saving grid ball mill is lined grooved ring plate which increases the contact surface of ball and ore and strengthens the grinding.

【Advantages】

Large double row self-aligning roller bearing with low friction force is used to replace sliding bearing, which is easy to start and saves 20-30% energy.

Cylindrical energy saving grid ball mill is lined grooved ring plate which increases the contact surface of ball and ore and strengthens the grinding.

Large ore outlet and large capacity;

The mill with diameter below 2.1 meters adopts whole machine frame, which is convenient for civil construction and equipment installation.

Oil mist lubrication device guarantees the lubrication of all gears

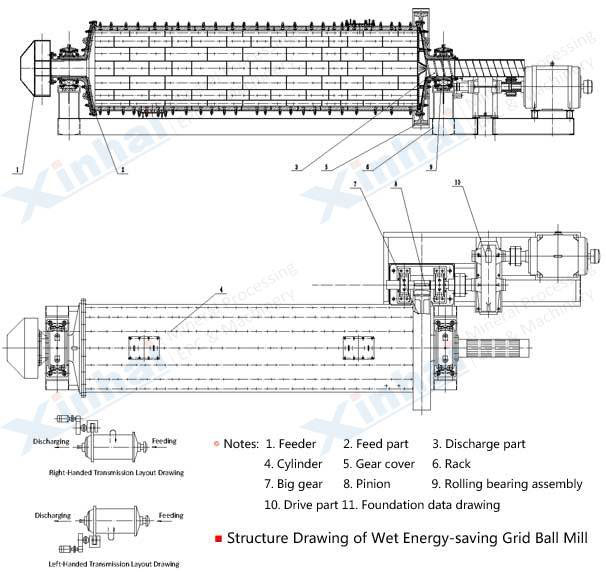

【Product Structure】

Cylindrical energy saving grid ball mill design consist of feeding part, discharging part, rotary part, transmission part (reducer, small gear, motors, electrical control) and other major parts. Hollow shaft is steel castings, and the liner is detachable. Rotary gear is processed by casting hobbing. The cylinder is lined wear-resistant liner plate with good resistance to wear. This machine works stably.

【Technical Parameters】

| Model | Cylinder

Diameter

(mm) | Cylinder

Length

(mm) | Motor Model | Motor

Power

(kW) | Length

(mm) | Width

(mm) | Height

(mm) | Capacity

(t/h) | Effective

Volume

(m3) | Max. Ball Load (t) | Weight

(kg) |

| MQGg 1212 | 1200 | 1200 | Y200L2-6 | 22 | 3512 | 2076 | 1620 | 0.17 ~4.1 | 1.14 | 2.4 | 9610 |

| MQGg 1224 | 1200 | 2400 | Y280M-8 | 45 | 5745 | 2352 | 1778 | 0.26~6.15 | 2.4 | 4.6 | 12692 |

| MQGg 1240 | 1200 | 4000 | JR117-8 | 80 | 7990 | 2210 | 2262 | 0.34~8.3 | 3.8 | 7.8 | 15932 |

| MQGg 1515 | 1500 | 1500 | Y280M-8 | 45 | 5740 | 3075 | 2280 | 1.4 ~4.5 | 2.2 | 5 | 17125 |

| MQGg 1530 | 1500 | 3000 | JR117-8 | 80 | 7253 | 3070 | 2280 | 2.8 ~9 | 5 | 10 | 21425 |

| MQGg 1536 | 1500 | 3600 | JR126-8 | 110 | 8595 | 3185 | 2280 | 3~11 | 5.4 | 11.4 | 24213 |

| MQGg 1545 | 1500 | 4500 | JR127-8 | 130 | 9680 | 3254 | 2370 | 3.5~12.5 | 7 | 12 | 27346 |

| MQGg 1830 | 1800 | 3000 | JR136-8 | 180 | 8250 | 3620 | 2785 | 4.5 ~27 | 6.65 | 14 | 31850 |

| MQGg 1836 | 1800 | 3600 | JR136-8 | 180 | 8866 | 3683 | 2785 | 4.5 ~29 | 8.2 | 13.8 | 35467 |

| MQGg 1845 | 1800 | 4520 | JR137-8 | 210 | 9808 | 3683 | 2785 | 5~35 | 10.2 | 19 | 38909 |

| MQGg 1856 | 1800 | 5620 | JR137-8 | 210 | 10909 | 3683 | 2785 | 6~40 | 12.2 | 22 | 41681 |

| MQGg 1870 | 1800 | 7020 | JR138-8 | 245 | 12404 | 3783 | 2735 | 7~50 | 15 | 31.5 | 45166 |

| MQGg 2122 | 2100 | 2200 | JR128-8 | 155 | 7135 | 4137.7 | 3083 | 5~29 | 6.6 | 20 | 38340 |

| MQGg 2130 | 2100 | 3000 | JR136-8 | 180 | 8220 | 4220 | 3083 | 6.5 ~36 | 9 | 27 | 43100 |

| MQGg 2136 | 2100 | 3600 | JR137-8 | 210 | 9154.5 | 4320 | 3433 | 7.5 ~42 | 10.8 | 23.5 | 45833 |

| MQGg 2140 | 2100 | 4000 | JR137-8 | 210 | 9654 | 4320 | 3083 | 7.5 ~45 | 12.8 | 22.5 | 47262.4 |

| MQGg 2145 | 2100 | 4500 | JR137-6 | 280 | 10350 | 4253 | 3125 | 10 ~50 | 13.5 | 23.6 | 52648 |

| MQGg 2230 | 2200 | 3000 | JR137-8 | 210 | 8220 | 3864 | 3183 | 7.5 ~45 | 9.8 | 20.6 | 44600 |

| MQGg 2430 | 2400 | 3000 | JR138-8 | 280 | 9023.5 | 4836.4 | 3490 | 7.2 ~92 | 11.5 | 22.5 | 59544.5 |

| MQGg 2436 | 2400 | 3600 | JR138-8 | 320 | 9604.5 | 4836.4 | 3490 | 8 ~100 | 13.8 | 25.5 | 63932.5 |

| MQGg 2442 | 2400 | 4200 | JR138-8 | 320 | 10204.5 | 4836.4 | 3490 | 8 ~110 | 16 | 30 | 67370 |

| MQGg 2721 | 2700 | 2100 | JR138-8 | 245 | 8300 | 4786.4 | 3495 | 7.2 ~84 | 10.7 | 23 | 66743 |

| MQGg 2727 | 2700 | 2700 | JR137-6 | 280 | 8901 | 4786.4 | 3490 | 7 ~110 | 13.8 | 29 | 71030 |

| MQGg 2730 | 2700 | 3000 | JR1410-8 | 320 | 9610 | 5000 | 3495 | 8 ~115 | 15.3 | 32 | 83909.2 |

| MQGg 2732 | 2700 | 3200 | JR1410-8 | 320 | 10724 | 5000 | 3620 | 8 ~120 | 15.7 | 32 | 88073 |

| MQGg 2736 | 2700 | 3600 | JR158-8 | 380 | 10409 | 5150 | 3620 | 12~145 | 17.7 | 37 | 95300 |

| MQGg 2740 | 2700 | 4000 | JR158-8 | 380 | 10609 | 5150 | 3620 | 12.5 ~152 | 19 | 42 | 98454 |

| MQGg 2745 | 2700 | 4500 | JR1510-8 | 450 | 11534 | 5200 | 3670 | 13~160 | 22 | 40 | 100016 |

| MQGg 2747 | 2700 | 4700 | JR1510-8 | 475 | 11779 | 5571 | 4175 | 13~170 | 23 | 45 | 101645 |

| MQGg 2760 | 2700 | 6000 | JR1512-8 | 630 | 13299 | 5540.6 | 5140 | 15~200 | 30 | 60 | 119546 |

| MQGg 2836 | 2800 | 3600 | JR1510-8 | 400 | 10964 | 5350 | 3670 | 13~160 | 19.7 | 41 | 106350 |

| MQGg 3231 | 3200 | 3100 | TDMK630-36 | 630 | 12750 | 6750 | 5150 | 14~180 | 22.5 | 45 | 115430 |

| MQGg 3245 | 3200 | 4500 | TDMK800-36 | 800 | 13896 | 7200 | 5152.5 | 95~110 | 32.8 | 65 | 147588 |

| MQGg 3645 | 3600 | 4500 | TDMK1250-40 | 1250 | 18280 | 7700 | 5496 | 115~170 | 41.5 | 76 | 195727 |

【Successful case】

In the early time of a dressing plant in Xinjiang, it adopted ordinary ball mill in grinding system, due to the lining board, the grinding caused discharge chunk and abnormal breakage of lining board, which led to the ball mill cannot operate normally. To solve this problem, the client selected Xinhai energy saving ball mill. The mill is lined grooved ring plate which strengthens the tenacity, and increases the contact surface of ball, strengthens the grinding effect, and easy to control material particle size. Eventually, the whole production runs efficiently.

【Related products】

Consult

Consult

Leave Message

Leave Message zz540045886@gmail.com

zz540045886@gmail.com