【Advantages】

High vacuum degree (vacuum degree -0.09~-0.098MPa), low moisture of cake.

High filtration precision, solid content of filtrate<50ppm, which can be recycle used in the system.

Energy saving up to 90%, low energy consumption, low running cost.

Filter cake cleaning system is installed.

PLC and computer integrate with automatic valve control; high degree of automation and low labor intensity.

Compact structure; small area taken; convenient maintenance.

Advanced drainage system ensures application in any running conditions.

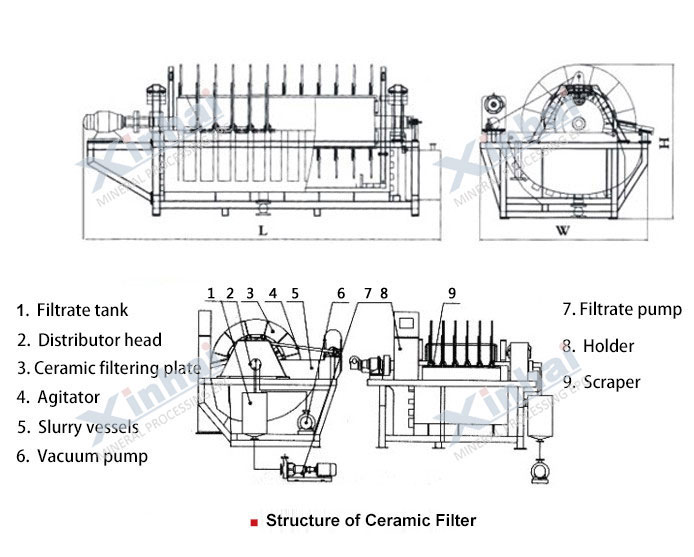

【Product Structure】

Pulp absorbing area: filter plate immersed in the pulp while in operation produces a surface absorption of filter cake, with the action of capillarity and integrated with vacuum pressure. Filtrate enters distributing valve and drainage tank through filter plate.

Spraying zone: filter cake receive spray washing after discharged from the slime hopper.

Drying zone: continuous dewatering for filter cake is conducted with the action of high vacuum force.

Discharging zone: scraper will automatically discharge materials once entering the vacuum-free condition.

Back Flushing: Service water or filtrate enters the ceramic plate through distributing valve and cleaning the blocked manhole. Cleaning with ultrasonic and low density acid after ceramic plate is used for one period to maintain the efficient service life of ceramic plate.

【Technical Parameters】

| Model |

Filter Area (m2) |

Number of Filter Disc (Circle) |

Number of Filter Plate (Piece) |

Tank

Volume

(m3) |

Installed

Power

(kW) |

Operation

Power

(kW) |

Main Frame

(LXWXH) (m) |

| TC-1 |

1 |

1 |

12 |

0.21 |

3.5 |

2.0 |

1.6X1.4X1.5 |

| TC-4 |

4 |

2 |

24 |

1.0 |

7.0 |

3.0 |

2.4X2.5X2.1 |

| TC-6 |

6 |

2 |

24 |

1.2 |

7.0 |

6.0 |

2.4X2.9X2.5 |

| TC-9 |

9 |

3 |

36 |

1.7 |

9.0 |

7.0 |

2.7X2.9X2.5 |

| TC-12 |

12 |

4 |

48 |

2.2 |

11.0 |

7.5 |

3.0X2.9X2.5 |

| TC-15 |

15 |

5 |

60 |

2.7 |

11.5 |

8.0 |

3.3X3.0X2.5 |

| TC-21 |

21 |

7 |

84 |

4.0 |

13.5 |

9.0 |

4.6X3.0X2.6 |

| TC-24 |

24 |

8 |

96 |

4.5 |

16.5 |

10.5 |

4.9X3.0X2.6 |

| TC-27 |

27 |

9 |

108 |

5.0 |

17.0 |

11.0 |

5.2X3.0X2.6 |

| TC-30 |

30 |

10 |

120 |

5.5 |

17.5 |

11.5 |

5.5 X 3.0 X 2.6 |

| TC-36 |

36 |

12 |

144 |

7.0 |

23.0 |

16.0 |

6.6X3.0X2.6 |

| TC-45 |

45 |

15 |

180 |

8.5 |

25.0 |

19.0 |

7.5X3.0X2.6 |

| TC-60 |

60 |

15 |

180 |

12.5 |

33.0 |

22.0 |

7.5X3.3X3.0 |

| TC-80 |

80 |

20 |

240 |

16.2 |

40.0 |

24.0 |

9.0X3.3X3.0 |

| TC-102 |

102 |

17 |

204 |

18.5 |

53.0 |

35.0 |

8.8X3.6X3.3 |

| TC-120 |

120 |

20 |

240 |

20 |

60.0 |

40.0 |

9.7X 3.6X 3.3 |

| TC-150 |

150 |

25 |

300 |

24 |

75.0 |

47.0 |

11.2X3.6X3.3 |

【Successful case】

A large mineral plant in Guangxi suffered from the problem that dehydrated level cannot meet the requirements, then recommended by the insider, the client found Xinhai Mining Technology & Equipment Inc. According to the terrain of Guangxi and the features of ore, Xinhai technology personnel recommended Xinhai ceramic vacuum filter with cheap prices, high efficiency, large capacity and low water content, the energy saving is more than 80%, the effluent water is clear, which can be recycled. Customers are very satisfied with it.

【Related products】

Consult

Consult

Leave Message

Leave Message zz540045886@gmail.com

zz540045886@gmail.com