【Advantages】

Strong agitation force; nice moving trace of slurry; suitable for the selection of coarse ore with bigger gravity and high sedimentation rate

Uniform mixing of slurry, air and reagents

Rapid flotation speed

Easy to restart after stopping

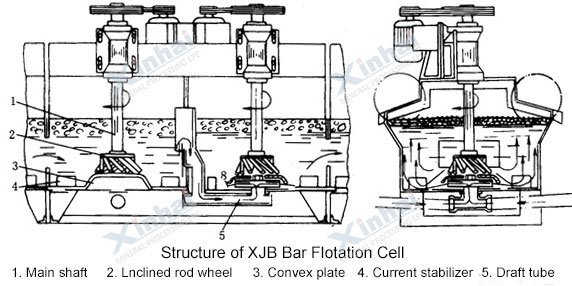

【Product Structure】

Bar flotation cell has air inflation agitation group consisting of oblique rod wheel, convex plate, arc stabilizer, etc.

Impeller is consisted of a disc and 12 bevel cone bars.

The rotating speed of bevel cone bar gets faster and faster while downing and agitation force gets stronger accordingly.

【Technical Parameters】

| Model |

Tank Type |

Effective Volume(m3) |

Capacity(m3/min) |

Impeller Diameter(mm) |

Impeller Rotation Speed(r.p.m) |

Motor Power for Agitation(kw) |

Motor Power for Scraper(kw)) |

4 Tank Weight(kg) |

| XJB-1 |

Suction Tank |

1 |

1.5-1.7 |

400 |

440 |

5.5 |

1.5 |

5344 |

| XJB-1 |

Direct Flow Cell |

1 |

1.5-1.7 |

410 |

410 |

4 |

0.8 |

5344 |

| XJB-1D |

Suction Tank |

1 |

1.5-1.7 |

400 |

440 |

5.5 |

1.5 |

5479 |

| XJB-1D |

Direct Flow Cell |

1 |

1.5-1.7 |

410 |

410 |

4 |

0.8 |

5479 |

| XJB-2 |

Suction Tank |

2 |

1.5-1.4 |

450 |

360 |

15 |

1.1 |

9071 |

| XJB-2 |

Direct Flow Cell |

2 |

1.5-1.4 |

540 |

360 |

11 |

1.1 |

9071 |

| XJB-2D |

Suction Tank |

2 |

1.5-1.4 |

450 |

360 |

15 |

1.1 |

9320 |

| XJB-2D |

Direct Flow Cell |

2 |

1.5-1.4 |

540 |

360 |

11 |

1.1 |

9320 |

| XJB-4 |

Suction Tank |

4 |

2.0-4 |

700 |

280 |

18.5 |

1.1 |

16325 |

| XJB-4 |

Direct Flow Cell |

4 |

2.0-4 |

510 |

280 |

18.5 |

1.1 |

16325 |

【Successful case】

A copper ore dressing plant in Anhui chose Xinhai EPC service. In the flotation process, considered the ore proportion is much big, and the granularity is coarser, Xinhai designed and updated XJB bar flotation cell for it, adopted high manganese steel-casting steel bar, the wear-resisting performance is greatly improved, solving the low durability of previous bar type flotation equipment. In flotation process, the capacity is up to 3000 t/d, and the energy costs are relatively low.

【Related products】

Consult

Consult

Leave Message

Leave Message zz540045886@gmail.com

zz540045886@gmail.com