【Advantages】

Scientific and reasonable design, decrease the damage to carbon.

High efficiency, the time of lifting carbon is 0.5~1 hours.

Small volume, it is convenient to install on leaching agitation tank or adsorption tank; convenient operation and maintenance.

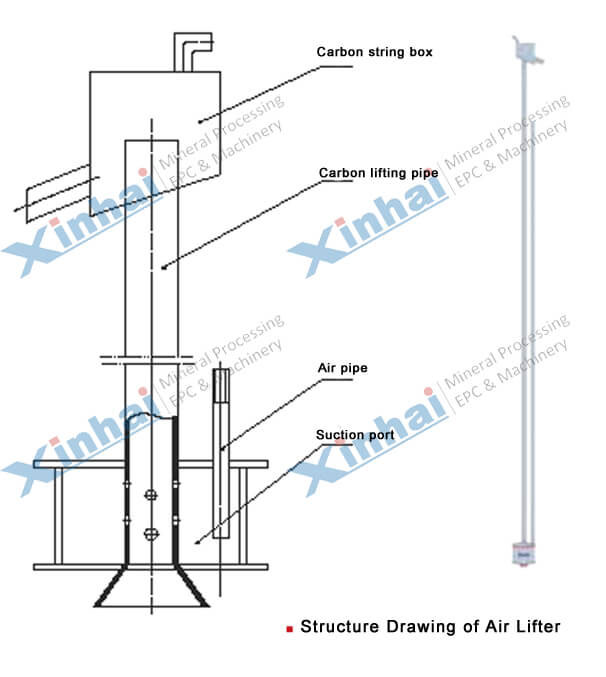

【Product Structure】

Pressure air is inflated into air lifter, which reduces the air density of ore pulp pipe and causes the pressure difference between pipe and tank. By the action of pressure, ore pulps in tank are lifted by air lifter.

【Technical Parameters】

| Model |

Carbon adsorption pipe specification |

Air pipe specification |

Application range |

| KT60 |

Φ50×2.5 |

DN20 |

SJ2.0×2.5, SJ2.5×2.5, SJ2.5×3.15, SJ3×3.15, SJ3×3.5, SJ3.15×3.55 |

| KT100 |

Φ108×4 |

DN25 |

SJ3.55×4, SJ4×4.5, SJ4.5×5, SJ5×5.6,SJ5.5×6, SJ7.5×8, SJ8×8.5 |

| KT125 |

Φ133×4 |

DN32 |

SJ8.5×9, SJ9×9.5, SJ10.5×11 |

| KT150 |

Φ159×4 |

DN40 |

SJ12×13 |

【Successful case】

In Zimbabwe's 100 pd rock gold mine project, as the supporting facilities of leaching tank, Xinhai air lifter improved the extracting carbon effect when leaching tank, effectively preventing the activated carbon to move along the direction of pulp; carbon screen makes an isolation effect on pulp flow in the leaching tank and activated carbon adsorption of gold, preventing the mixing of activated carbon and pulp, increasing extra work.

【Related products】

Consult

Consult

Leave Message

Leave Message zz540045886@gmail.com

zz540045886@gmail.com