- Home

- About

- Mineral Processing EPC+M+O

-

Product

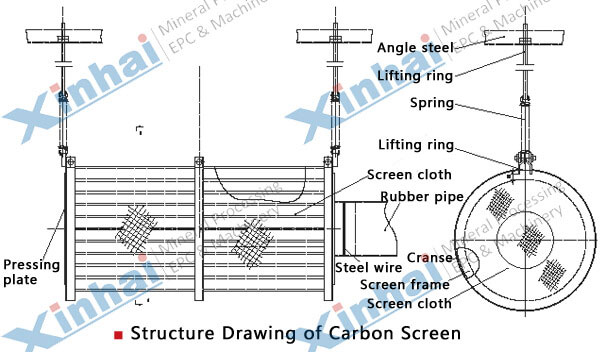

- Thickening & Dewatering

- Dewatering Machine

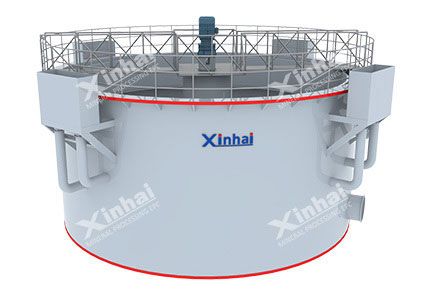

- Thickening

- Separating Process

- Gold Extraction Equipment

- Gravity Equipment

- Washing Equipment

- Magnetic Equipment

- Flotation

- Grinding & Classification

- Classifying

- Grinding

- Consumables

- Accessories

- Auxiliary Product

-

Solutions

Metal

Tailings

- Case

- News

- Contact

Consult

Consult

Leave Message

Leave Message zz540045886@gmail.com

zz540045886@gmail.com