【Advantages】

It has two methods to adjust the production capacity: adjusting the rotating speed of the AC motor; adjusting the depth of the adjusting gate.

Low power consumption, convenient operation.

Convenient installation, large conveying capacity. Low noise.

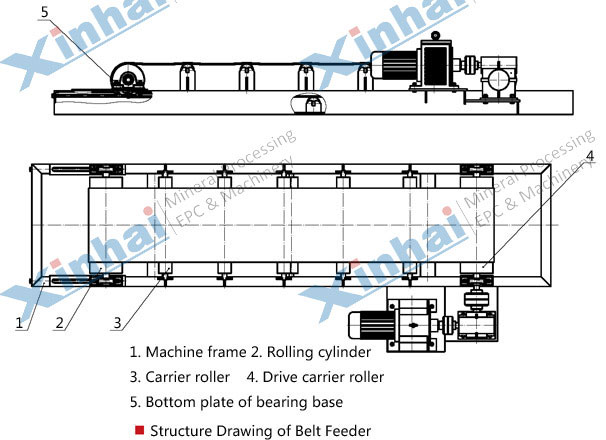

【Product Structure】

The hopper feeds minerals on the belt. With the AC motor revolving, belt slowly moves toward and carries minerals to next production process to achieve continuous feeding.

【Technical Parameters】

| Model |

Belt Width (mm) |

Center Distance of Head and Tail Wheel or Drum Wheel (mm) |

Diameter of Head and Tail Wheel (mm) |

Feed Capacity (t/h) |

Feed Size (mm) |

Motor Model |

Motor

Power

(kW) |

Weight

(kg) |

| 500X1000 |

500 |

1000 |

219 |

10~100 |

0~50 |

YCT112- 4B |

0.75 |

266 |

| 500X1300 |

1300 |

10~100 |

0~50 |

YCT160 -4A |

2.2 |

345 |

| 500X1500 |

1500 |

10~100 |

0~50 |

Y2.2-1.0-50-32 |

2.2 |

767 |

| 500X2000 |

2000 |

10~100 |

0~50 |

Y2.2-1.0-50-32 |

2.2 |

609.4 |

| 500X2800 |

2800 |

10~100 |

0~50 |

YCT160- 4A |

2.2 |

670 |

| 500 X3000 |

3000 |

10~100 |

0~50 |

YCT160 -4A |

2.2 |

697 |

| 500 X4000 |

4000 |

10~100 |

0~50 |

YCT160- 4A |

2.2 |

736 |

| 650X1500 |

650 |

1500 |

10~100 |

0~50 |

YCT160- 4A |

2.2 |

610 |

| 650X2600 |

650 |

2600 |

10~100 |

0~50 |

YCT160- 4A |

2.2 |

636 |

| 650X4000 |

650 |

4000 |

10~100 |

0~50 |

YCT160- 4A |

2.2 |

893 |

| 800 X2000 |

800 |

2000 |

15~150 |

0~80 |

YCT160- 4A |

2.2 |

721 |

| 800 X3000 |

800 |

3000 |

15~150 |

0~80 |

YCT200- 4B |

7.5 |

857.3 |

| 800 X4000 |

800 |

4000 |

15~150 |

0~80 |

YCT200- 4B |

7.5 |

1012 |

| 800X4500 |

800 |

4500 |

400 |

15~150 |

0~80 |

YCT160- 4A |

2.2 |

1200 |

| 1000X2000 |

1000 |

2000 |

200~450 |

0~80 |

YCT160- 4B |

3 |

1549 |

| 1000X2500 |

2500 |

200~450 |

0 ~100 |

YCT160- 4B |

3 |

2105 |

| 1000 X6000 |

6000 |

200~450 |

0 ~100 |

YCT225- 4A |

11 |

5214 |

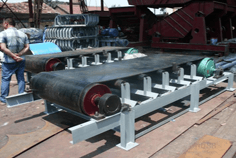

【Successful case】

A mineral processing plant in Henan needed a feeder that can transport 2t tungsten. At first, the client chose vibration motor that is often burned. Because the maintenance space is narrow, and there is no lifting facility, so the maintenance difficulty is large, and it is not safe. After discussion with technical personnel, the client decided to choose Xinhai belt feeder. Compared with the former, short-distant belt feeder has smooth operation with low noise, and it’s easy to maintain, the ore amount is adjustable, there is no potential safety hazard in the process of work, ensuring normal operation of the whole production line.

【Related products】

Consult

Consult

Leave Message

Leave Message zz540045886@gmail.com

zz540045886@gmail.com