【Advantages】

Stable working and easy operation.

Wide application, energy saving and efficient.

Large bearing capacity and stable operation.

Simple structure; even feeding; convenient maintenance; the best choice for feeding process of powder materials.

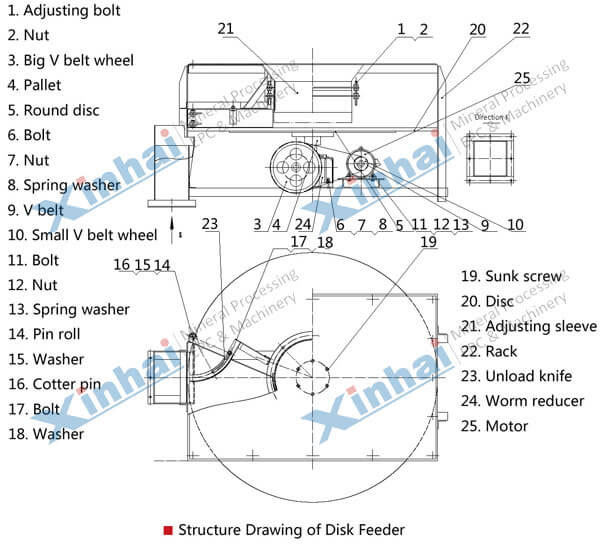

【Product Structure】

Bulky materials entering into the cylinder from the hopper accumulate by itself weight on the disk. The natural angle of material is controlled on the disk by adjusting the gap between the sleeve and disc. When the disk rotates, the materials are scraped into accepted hopper by unloading knife, so with the continuous rotation of the disk, the materials are fed evenly. Adjust the gap between the unloading knife and the disk to control the feeding volume.

【Technical Parameters】

| Type |

Model |

Disk Diameter (mm) |

Rotating Speed of Disk (r/min) |

Max. Feed Size (mm) |

Feed Capacity (t/h) |

Motor Model |

Motor Power

(kW) |

Weight

(kg) |

| |

YG300 |

300 |

10. 0 |

20 |

0~ 1. 8 |

Y80L- 4 |

0. 55 |

115 |

| |

YG400 |

400 |

10. 7 |

0~ 2. 6 |

Y90L- 6 |

1. 1 |

120 |

| |

YG500 |

500 |

0~ 3. 3 |

124 |

| Close |

YG600 |

600 |

10. 0 |

0~5. 0 |

130 |

| Hanged |

YG800 |

800 |

9 |

30 |

0~8. 0 |

Y80L- 4 |

0.55 |

195 |

| |

YG1000 |

1000 |

9 |

30 |

0~ 12 |

Y90L- 4 |

1. 5 |

263 |

| |

YG1500 |

1500 |

7 |

40 |

0~ 22 |

Y132M2-6 |

5. 5 |

755 |

| |

YG2000 |

2000 |

5 |

50 |

0〜80 |

Y160L-6 |

11 |

2517 |

| |

DK600 |

600 |

7. 53 |

25 |

1. 8~ 3. 9 |

Y90L- 6 |

1. 1 |

410 |

| |

DK800 |

800 |

7. 53 |

30 |

3. 5~ 7. 6 |

600 |

| |

DK1000 |

1000 |

7. 50 |

40 |

1.8〜16.7 |

Y100L- 6 |

1. 5 |

725 |

Open

Hanged |

DK1300 |

1300 |

6. 5 |

50 |

4. 3~27. 9 |

Y132S- 6 |

3 |

846 |

| DK1600 |

1600 |

6 |

60 |

7.03~48.6 |

Y132M1- 6 |

4 |

1980 |

| |

DK1800 |

1800 |

5 |

70 |

9.26~60 |

Y132M2- 6 |

5.5 |

3070 |

| |

DK2000 |

2000 |

80 |

13.6~88.4 |

Y132M2- 6 |

3260 |

【Successful case】

An iron processing plant in Shandong purchased Xinhai disc type feeder, it adopts fusing porcelain plate with strong scour resistance and strong grinding capacity, and there is no leakage even equipment damage and other accidents in practical application, which has higher equipment safety than others, ensuring the smooth operation of the production. Disc feeder feeds the material into another device evenly so that the process can work normally, saving labor and protecting the equipment performance, prolonging feeding equipment service life in the whole production line.

【Related products】

Consult

Consult

Leave Message

Leave Message zz540045886@gmail.com

zz540045886@gmail.com