【Advantages】

Stable operation, reliable work, long service life, continuous and feeding for crushing, rough screening, and it is widely used in mineral processing, building materials, silicate and chemical industry etc.

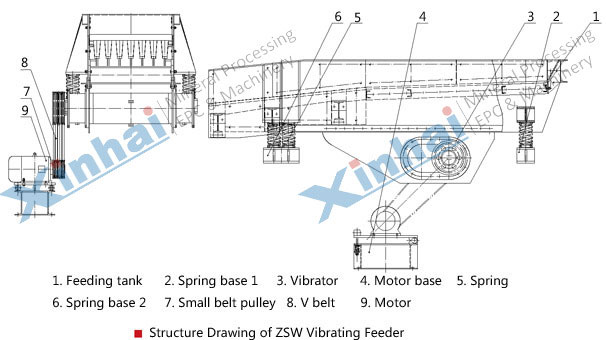

【Product Structure】

The vibration exciter is composed of two eccentric shafts with particular position. The large linear vibration force produced by motor and the rotation of two eccentric shafts vibrates the machine. The materials are sliding and thrown so that it could move on. When the materials pass the screen bars, the small ore falls through the clearance of screen bars.

【Technical Parameters】

| Model |

Tank Dimensions (mm) |

Max. Feed Size (mm) |

Feed Capacity (t/h) |

Rotating Speed of Eccentric Shaft (r/min) |

Motor Power

(kW) |

Weight

(kg) |

| ZSW380X95 |

3800X950 |

500 |

96~160 |

800 |

11 |

4082 |

| ZSW420X110 |

4200X1100 |

500 |

110~180 |

800 |

15 |

4149 |

| ZSW490X110 |

4900X1100 |

500 |

115~192 |

800 |

15 |

4263 |

| ZSW590X110 |

5900X1100 |

630 |

350~500 |

800 |

22 |

6130 |

| ZSW600X130 |

6000X1300 |

750 |

400~560 |

800 |

7800 |

【Successful case】

A chemical plant in Guizhou planned to purchase two vibrating feeder from Xinhai, considering the particularity of equipment requirements that is strict with material PH valve, therefore Xinhai improved the ZSW vibrating feeder, adopted alloy steel plate to form a trough, ensuring the materials with serious temperature wear and corrosive substance has no influence in the process of delivery. The capacity of this type feeder is strong, which can work ten hours per day, feed ore materials about 10000t, the efficiency is very high, so it is favored by lots of customers. The price of vibrating feeder is suitable

【Related products】

Consult

Consult

Leave Message

Leave Message zz540045886@gmail.com

zz540045886@gmail.com