Autogenous Mill

【Introduction】:A wet autogenous mill that materials as grinding media

【Capacity】: 200-350mm

【Improvement】: High-efficiency autogenous mill can realize the second and third stage crushing and screening, and part or all crushing and grinding of rod mill or ball mill. Low power consumption, no dust pollution, less auxiliary equipment, easy production automation, and stable particle size.

【Advantages】

Simplify the crushing and grinding process; feeding particle size is 200-350mm, and after the first autogenous grinding, the product particle size reaches below a few millimeter.

It is suitable for ore with high content of mud and water; small area taken, low investment

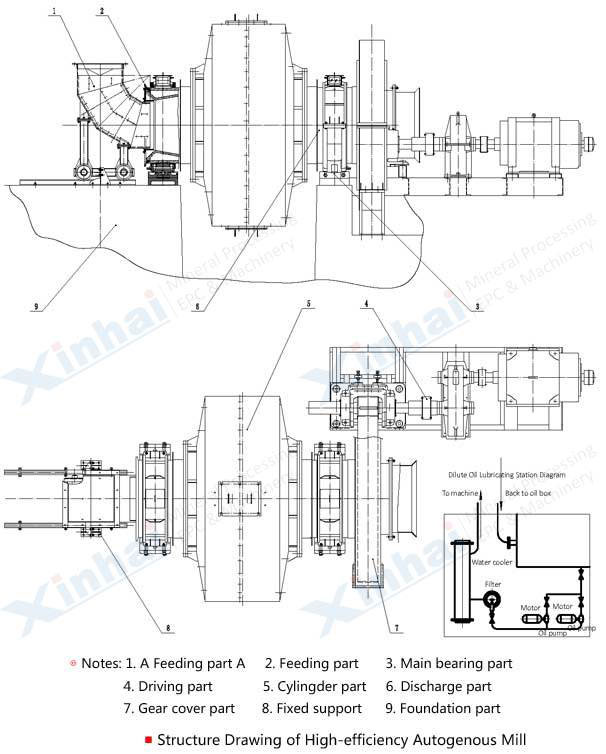

【Product Structure】

Except for few hard ore, most of metal ores could use wet autogenous mill.

【Technical Parameters】

| Model |

Diameter (mm) |

Length (mm) |

Feed Size (mm) |

Main Motor |

| Model |

Power (kW) |

Voltage (V) |

Weight (t) |

| ZMJ4014 |

4000 |

1400 |

< 350 |

JR148-8 |

245 |

10000 |

75 |

| ZMJ4018 |

4000 |

1800 |

< 350 |

JR1410-8 |

320 |

10000 |

82 |

| ZMJ5518 |

5500 |

1800 |

< 400 |

TDMK800-36 |

800 |

10000 |

175 |

| ZMJ6522 |

6500 |

2200 |

< 400 |

TDMK1600-40 |

1600 |

10000 |

280 |

| ZMJ7525 |

7500 |

2500 |

< 400 |

TM2500-16 |

2500 |

10000 |

455 |

| ZMJ7528 |

7500 |

2800 |

< 400 |

TM2500-16 |

2500 |

10000 |

465 |

【Successful case】

In Vietnam iron ore dressing plant, the ore capacity is larger, and the auxiliary equipment under the cost control has a small quantity. In this case, Xinhai efficient autogenous mill solved these problems effectively. Xinhai efficient autogenous mill can achieve two and three stage crushing, part or all crushing of ball mill and rod mill, it is suitable for the coarse grinding after coarse crushing. Finally, in the actual production, Xinhai efficient autogenous mill improved production efficiency, controlled the cost in the operation, the customer is very satisfied with the result.

【Related products】

Consult

Consult

Leave Message

Leave Message zz540045886@gmail.com

zz540045886@gmail.com