【Advantages】

The transmission machinery of Energy-saving overflow ball mill substitutes large-scale double row self-aligning roller bearing for sliding bearing, so it is easy to start and saves energy by 20-30%.

Energy-saving overflow ball mill adopts groove-type circular lining plate that is instrumental in increasing contact areas of iron balls and ores, which enhances grinding action and ore lifting capacity and decreases energy consumption.

Energy-saving overflow ball mill is configured with bigger discharge opening and has huge processing capacity.

Energy-saving overflow ball mill adopts whole milling house, which makes construction and installation easy.

Energy-saving overflow ball mill is equipped with oil-mist lubrication device which guarantees smooth operation of gears.

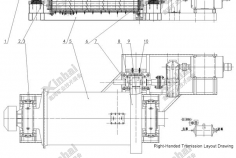

【Product Structure】

The main component is a cylinder with diameter and length at a reasonable proportion. Driven by the transmission device, the cylinder rotates with the materials fed from the cylinder inlet and crushed by the falling impacts and autogenous grinding of the steel balls and ores in the cylinder. Due to the continuously feeding materials, the pressure pushes materials to the outlet and the grinded materials are discharged from the cylinder outlet. Qualified materials flow from the cylinder outlet. In wet grinding, the materials are taken out by the water flow. There are backpitch impellers in the hollow shaft, which can make the balls and coarse ores in the overflow return to the mill. With simple structure, higher operation rate, and rolling bearing, the energy conservation is significant.

【Technical Parameters】

| Model |

Cylinder

Diameter

(mm) |

Cylinder

Length

(mm) |

Motor

Model |

Motor Power

(kW) |

Length

(mm) |

Width

(mm) |

Height

(mm) |

Capacity

(t/h) |

Effective

Volume

(m3) |

Max. Ball Load (t) |

Weight

(kg) |

| MQYg 0912 |

900 |

1200 |

Y1800L-6 |

15 |

3666 |

1835 |

1400 |

0.25〜1.2 |

0.7 |

1 |

4265 |

| MQYg 0918 |

900 |

1800 |

Y225M-8 |

22 |

4401 |

2535 |

2070 |

0.25〜1.6 |

0.9 |

1.66 |

5235 |

| MQYg 1212 |

1200 |

1200 |

Y225S-8 |

18.5 |

3512 |

2076 |

1620 |

0.17 〜4.1 |

1.14 |

1.9 |

9610 |

| MQYg 1224 |

1200 |

2400 |

Y280M-8 |

45 |

5745 |

2352 |

1778 |

0.26〜6.15 |

2.4 |

4.6 |

12219 |

| MQYg 1240 |

1200 |

4000 |

JR117-8 |

80 |

7990 |

2412 |

1728 |

0.34 〜8.3 |

3.7 |

8 |

15940 |

| MQYg 1515 |

1500 |

1500 |

Y280M-8 |

45 |

5740 |

3075 |

2280 |

1.4 〜4.5 |

2.2 |

4.2 |

17125 |

| MQYg 1530 |

1500 |

3000 |

JR117-8 |

80 |

7253 |

3070 |

2280 |

2.8 〜9 |

5 |

10 |

21129 |

| MQYg 1536 |

1500 |

3600 |

JR126-8 |

110 |

8595 |

3185 |

2280 |

2.8 〜10 |

5.4 |

10 |

23933 |

| MQYg 1545 |

1500 |

4500 |

JR127-8 |

130 |

9680 |

3254 |

2370 |

3.5〜12.5 |

7 |

12 |

27500 |

| MQYg 1557 |

1500 |

5700 |

JR127-8 |

130 |

10880 |

3254 |

2370 |

4.5 〜16 |

8.9 |

15 |

29359 |

| MQYg 1836 |

1800 |

3620 |

JR136-8 |

180 |

8865 |

3683 |

2785 |

4.5 〜29 |

8.2 |

13.8 |

34970 |

| MQYg 1845 |

1800 |

4520 |

JR137-8 |

210 |

9750 |

3683 |

2785 |

5〜33 |

10.2 |

19 |

37480 |

| MQYg 1857 |

1830 |

5720 |

JR137-8 |

210 |

11009 |

3683 |

2785 |

6〜40 |

12.5 |

22 |

42096 |

| MQYg 1863 |

1800 |

6320 |

JR138-8 |

320 |

11690 |

3781 |

2775 |

6〜45 |

14.2 |

25 |

45520.5 |

| MQYg 1870 |

1800 |

7020 |

JR138-8 |

245 |

12599 |

3783 |

2735 |

7〜47 |

15 |

31.5 |

45136 |

| MQYg 1875 |

1800 |

7520 |

JR138-8 |

245 |

12850 |

3783 |

2775 |

7.5 〜54 |

17 |

30 |

49450 |

| MQYg 2122 |

2100 |

2200 |

JR128-8 |

155 |

7235 |

4120 |

3083 |

5〜29 |

6.6 |

20 |

35963 |

| MQYg 2130 |

2100 |

3000 |

JR136-8 |

180 |

8220 |

4220 |

3083 |

6.5 〜36 |

9 |

27 |

40157 |

| MQYg 2136 |

2100 |

3600 |

JR137-8 |

210 |

8958 |

4320 |

3025 |

7.5 〜42 |

10.8 |

23.5 |

44132.5 |

| MQYg 2145 |

2100 |

4500 |

JR138-8 |

245 |

10350 |

4268 |

3121 |

10 〜45 |

13.5 |

23.6 |

42772 |

| MQYg 2430 |

2400 |

3000 |

JR138-8 |

280 |

9023.5 |

4836.4 |

3490 |

7.2 〜92 |

11.5 |

22.5 |

57455.5 |

| MQYg 2436 |

2400 |

3600 |

JR137-6 |

280 |

9623.5 |

4836.4 |

3490 |

8 〜110 |

13.8 |

25.5 |

60861.5 |

| MQYg 2442 |

2400 |

4200 |

JR138-8 |

320 |

10204.5 |

4836.4 |

3440 |

8 〜130 |

16.5 |

31.5 |

63829.5 |

| MQYg 2445 |

2400 |

4500 |

JR1510-8 |

380 |

11132.5 |

5091.4 |

4065 |

8.5 〜140 |

17.5 |

31 |

75923 |

| MQYg 2460 |

2400 |

6000 |

JR1510-8 |

450 |

12623.5 |

5201.4 |

4060 |

9 〜180 |

23 |

40 |

83869 |

| MQYg 2727 |

2700 |

2700 |

JR137-6 |

280 |

8901 |

4786.4 |

3620 |

7 〜110 |

13.8 |

29 |

66201 |

| MQYg 2730 |

2700 |

3000 |

JR137-6 |

280 |

9201 |

4786.4 |

3620 |

8 〜115 |

15.3 |

32 |

72415 |

| MQYg 2732 |

2700 |

3200 |

JR1410-8 |

320 |

10729 |

5000 |

3620 |

8〜120 |

15.7 |

32 |

83110 |

| MQYg 2736 |

2700 |

3600 |

JR158-8 |

380 |

10764 |

5150 |

3620 |

12〜145 |

17.7 |

37 |

90441 |

| MQYg 2740 |

2700 |

4000 |

JR1510-8 |

380 |

10870 |

5050 |

3620 |

12.5 〜152 |

19 |

40 |

93537 |

| MQYg 2745 |

2700 |

4500 |

JR1510-8 |

380 |

11664 |

5150 |

3620 |

12.5 〜163 |

20.5 |

40 |

96196 |

| MQYg 2747 |

2700 |

4700 |

JR1510-8 |

450 |

11864 |

5150 |

3620 |

13〜170 |

23 |

45 |

97605 |

| MQYg 3231 |

3200 |

3100 |

TDMK630-36 |

630 |

12550 |

6750 |

5150 |

14〜180 |

21.4 |

45 |

112430 |

| MQYg 3245 |

3200 |

4500 |

TDMK630-36 |

630 |

13950 |

7200 |

5152.5 |

95〜110 |

32.8 |

65 |

141629 |

| MQYg 3660 |

3600 |

6000 |

TDMK1250-40 |

1250 |

19780 |

7700 |

5496 |

120〜200 |

55 |

102 |

193483 |

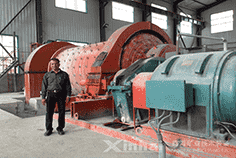

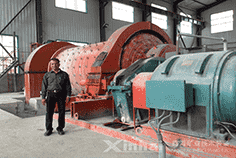

【Successful case】

At the early stage of the establishment of a concentrator in xinjiang, the grinding system used an ordinary ball mill, which could not work normally due to the abnormal fracture of the lining plate and the throwing out of large pieces. To solve this problem, the customer chose xinhai wet energy saving grid ball mill. The ball mill adopts corrugated lining plate, while the toughness is enhanced, the contact area of ball ore is enlarged, the grinding effect is strengthened, and the particle size of material is more controllable. Finally, the whole production process is carried out efficiently.

【Related products】

Consult

Consult

Leave Message

Leave Message zz540045886@gmail.com

zz540045886@gmail.com