【Advantages】

Compact structure, reliable quality.

Wide application, high efficiency.

Advanced technology.

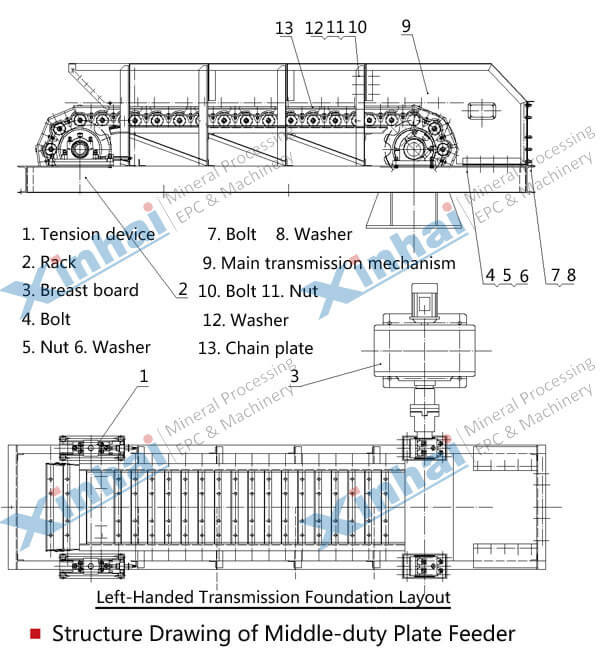

【Product Structure】

Plate feeder .has light type, medium type and heave type.

Medium and heavy type are the common plate feeder consisting of.

1, Transmission device: motor, speed reducer, coupling etc. ;

2, Head wheel: head frame, driving shaft, chain wheel, transmission shaft and front frame.

3、Chain

4、Chain plate

5、Tail wheel: chain wheel, rear rack, tension device etc.

6、Support and side board

7、Intermediate frame

【Technical Parameters】

| Model |

Chain Plate |

Feed

Size

(mm) |

Capacity

(m3/h) |

Motor |

Overall Dimension (LXWXH) (mm) |

Weight

(kg) |

Width

(mm) |

Center Distance of Chain Wheel (mm) |

Speed

(m/s) |

Model |

Power

(kW) |

| GBH80-2.2 |

800 |

2200 |

0.01 ~0.053 |

≤300 |

15 ~91 |

Y132M-4 |

7.5 |

3840X2850X1185 |

3722 |

| GBH80-3 |

3000 |

XWED106-385-4 |

4 |

4868X2705X1060 |

4014 |

| GBH80-4 |

4000 |

Y132M-4 |

|

5640X2986X1185 |

5087 |

| GBH80-5.8 |

5800 |

0.18 |

≤300 |

15 ~91 |

XWED7.5-8215A-231 |

7.5 |

7760x2823.5x1321 |

6526.7 |

| GBH100-1.6 |

1000 |

1600 |

≤0.15 |

≤350 |

22~131 |

Y160M-6 |

3240X3026X1235 |

3981 |

| GBH100-3 |

3000 |

|

4640X3114X1235 |

4548 |

| GBH100-4 |

4000 |

0.01 ~0.053 |

22~131 |

XWED106-385-4 |

4 |

5648x2890x1160 |

5086 |

| GBH120-1.8 |

1200 |

1800 |

≤0.15 |

300-400 |

35~217 |

Y160M-6 |

7.5 |

3440X3314X1235 |

3965 |

| GBH120-2.2 |

2200 |

3840X3314X1285 |

4238 |

| GBH120-2.6 |

2600 |

4240X3314X1285 |

4572 |

| GBH120-3 |

3000 |

XWED7.5-8215A-273 |

4960X3150X1434 |

4886(Exclude

Reducer) |

| GBH120-4 |

4000 |

Y160M-6 |

5640X3402.5X1285 |

6100 |

| GBH120-4.5 |

4500 |

XWED7.5-8215A-273 |

6460X3150X1434 |

6350.6

(Exclude

Reducer) |

| GBH120-6 |

6000 |

300-400 |

35~217 |

XWED11-8225B-273 |

11 |

7960x3242x1434 |

8210 |

【Successful case】

One of our plate feeder in processing line. Xinhai is an feeder manufacturer. Light plate feeder is an important in ore conveying system. It is to transport ore to primary crusher for evenly and continuously feeding, and also for short-distance material delivery.

【Related products】

Consult

Consult

Leave Message

Leave Message zz540045886@gmail.com

zz540045886@gmail.com